The welded plate heat exchanger is assembled of a packet of corugated plates, one behind the other and welded together by unique TIG method welding machines.

(download of general technical information)

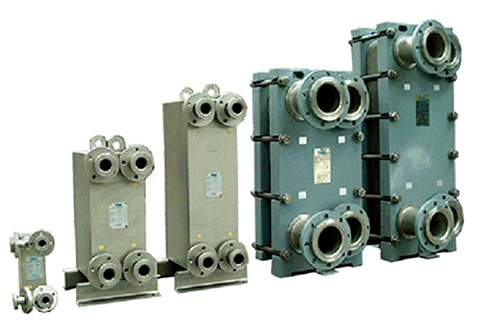

(click on the chosen type for technical details)

| STANDARD RANGE PN 10, 16, 25, 40 | |||

|---|---|---|---|

| Type | Connecting Size | Distance conn. Horizontal | Distance conn. Vertical |

| WST03 | DN25 | 50 | 250 |

| WST12 | DN50 | 166 | 490 |

| WST18 | DN50 | 166 | 734 |

| WST30 | DN150 (DN100) | 255 | 710 |

| WST40 | DN150 (DN100) | 255 | 1010 |

| Plates - standard material: | AISI 304 (1.4301); AISI 316 L (1.4404); AISI 316 Ti (1.4571) |

|---|---|

| Plates - special material: | AISI 904 L (1.4539); SMO 254 (1.4547); Nickel Alloys; Titanium, Titanium-PD |

| Thickness of sheet: | 0.6 mm |

| Welded Frame: | Stainless Steel (1.4571); Painted Carbon Steel |

| Connections - standard material: | AISI 316Ti, (1.4571) |

Available all common type of conections